Supply Inconel, Monel, Cobalt & Beryllium Alloys

offer an Extensive Range of Material Grades

Super Alloy materials, including Inconel, Monel, Hastelloy, Cobalt, Beryllium alloys, exhibit extraordinary properties: high strength, high wear resistance, high-temp stability or extreme corrosion resistance, and are mainly used in critical operating environments in petrochemical, marine and power plant industries. Click here to find essential knowledge about superalloys.

hastelloy

C22; C276

Inconel

Inconel 600, Inconel 625, Inconel 718

Incoloy

Alloy 20, Incoloy 800/800H, Incoloy 825

Cobalt Alloy

Stellite 3

Stelite 6B

Monel

Monel 400

Beryllium Cooper

CDA172

Our Key Advantages

Superalloys + Machining

Accept Low Qty Order

Short Lead Time

Our Manufacturing Process of Inconel & Monel

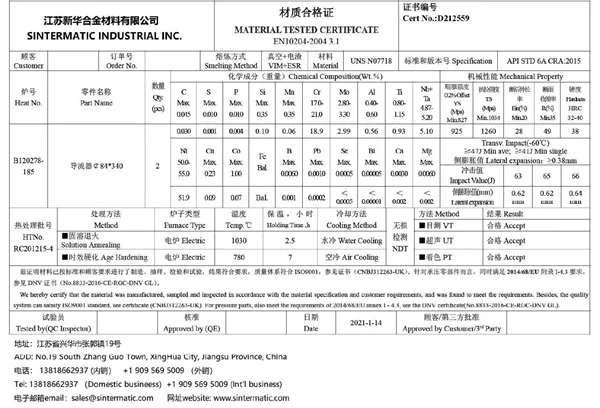

Process Inspection & Cert of Inconel, Monel …

Process

We implement state of art melting process: Vacuum Melting -> ESR -> Forging -> Heat Treatment -> Machining.

Inspection

We conduct chemical composition inspection, mechanical properties test and other NDTs (PT and UT) for each heat log.

Quality Certification

Material Specification

Hastelloy C22 and C276

These alloys exhibit excellent resistance to both oxidizing and reducing acid environments, as well as those containing mixed acids. It is particularly useful for resistance to pitting and crevice corrosion in acid-halide environments. The low carbon content minimizes carbide precipitation during welding to maintain corrosion resistance in as-welded structures.

| Chemical Composition | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Grade Symbal | UNS Designation | Carbon | Manganese | Phosphorus | Sulfur | Silicon | Chromium | Nickel | Molybdenum | Others | |

| Hastelloy C22 | UNS N06022 | 0.015 | 0.5 | 0.02 | 0.02 | 0.08 | 20.0-22.5 | Balance | 12.5-14.5 | Thungsten 2.5-3.0; Cobalt 2.5; Vanadium 0.35; | |

| Hastelloy C276 | UNS N10276 | 0.01 | 1 | 0.04 | 0.04 | 0.08 | 14.5-16.5 | Balance | 15.0-17.0 | Iron 4.0-7.0; Tungsten 3.0-4.5; Cobalt 2.5; Vandium 0.35; | |

| Mechanical Properities and ASTM Specifications | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Grade Symbal | UNS Designation | Condition | Tensile Strength | Tensile Strength | Yield Stegnth | Yield Strength | Elongation in 2in or 4D min% | Pipe | Pipe | Sheet | Bar | Forging | Fitting | |

| min ksi | min MPa | min ksi | min MPa | Smls | Plate | |||||||||

| Hastelloy C22 | UNS N06022 | Solution Annealed | 100 | 690 | 45 | 310 | 45 | B622 | B619 | B575 | B574 | B564 | B366 | |

| Hastelloy C276 | UNS N10276 | Solution Annealed | 100 | 690 | 41 | 283 | 40 | B622 | B575 | B574 | B564 | B366 | ||

Inconel 600, 625 and 718

These high strength alloys are designed to resist a wide range of severely corrosive environments, pitting and crevice corrosion.

| Chemical Composition | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Grade Symbal | UNS Designation | Carbon | Manganese | Phosphorus | Sulfur | Silicon | Chromium | Nickel | Molybdenum | Others | |

| Inconel 600 | UNS N06600 | 0.15 | 1 | … | 0.015 | 0.5 | 14.0-17.0 | 72.0 min | … | Cu 0.5; Iron 6.0-10.0 | |

| Inconel 625 | UNS N06625 | 0.1 | 0.035 | 0.015 | 0.015 | 0.5 | 20.0-23.0 | 58.0 min | 8.0-10.0 | Fe 5.0; Cobalt 1.0 max; Columbium+Tantalum 3.15-4.15; Al 0.40 max; Ti 0.40 max; | |

| Inconel 718 | UNS N07718 | 0.08 | 0.035 | 0.015 | 0.015 | 0.035 | 17.0-21.0 | 50.0-55.0 | 2.8-3.3 | Cu 0.3; Boron 0.006 max; Columbium+Tantalum 4.75-5.50; Ti 0.65-1.15; Cobalt 1.0 max | |

| Mechanical Properities and ASTM Specifications | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Grade Symbal | UNS Designation | Condition | Tensile Strength | Tensile Strength | Yield Stegnth | Yield Strength | Elongation in 2in or 4D min% | Reduction of Area, C, D min% | Brinell Hardness, HBW | Pipe | Bar | Forging | Fitting | |

| min ksi | min MPa | min ksi | min MPa | |||||||||||

| Inconel 600 | UNS N06600 | Annealed | 80 | 552 | 35 | 241 | 30 | B167 | B166 | B564 | B366 | |||

| Inconel 625 | UNS N06625 | Annealed | 120 | 60 | 30 | B444 | B446 | |||||||

| Inconel 718 | UNS N07718 | Solution + Precipitation harden | 185 | 1275 | 150 | 1034 | 12 | 15 | 331 min | B637 | ||||

Incoloy 800/800H, 825 and Alloy 20

These nickel steel alloys are designed to provide exceptional resistance to many corrosive environments. They have excellent resistance to both reducing and oxidizing acids, to stress-corrosion cracking, and to localized attack such as pitting and crevice corrosion.

| Chemical Composition | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Grade Symbal | UNS Designation | Carbon | Manganese | Phosphorus | Sulfur | Silicon | Chromium | Nickel | Molybdenum | Others | |

| Incoloy 800 | UNS N08800 | 0.1 | 1.5 | 0.045 | 0.015 | 1 | 19.0-23.0 | 30.0-35.0 | … | Fe 39.5 min; Cu 0.75; Al 0.15-0.60; Ti 0.15-0.60; | |

| Incoloy 800H | UNS N08810 | 0.1 | 1.5 | 0.045 | 0.015 | 1 | 19.0-23.0 | 30.0-35.0 | … | Fe 39.5 min; Cu 0.75; Al 0.15-0.60; Ti 0.15-0.60; | |

| Incoloy 825 | UNS NO8825 | 0.05 | 1 | 0.03 | … | 0.5 | 19.5-23.5 | 38.0-46.0 | 2.5-3.5 | Fe 22.0 min; Cu 1.5-3.0; Ti 0.6-1.2; Al 0.2; | |

| Alloy 20 | UNS N08020 | 0.07 | 2 | 0.045 | 0.03 | 1 | 19.0-21.0 | 32.0-38.0 | 2.0-3.0 | Cu 3.0-4.0; Nb 8 x C min 1.00 max; | |

| Mechanical Properities and ASTM Specifications | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Grade Symbal | UNS Designation | Condition | Tensile Strength | Tensile Strength | Yield Stegnth | Yield Strength | Elongation in 2in or 4D min% | Reduction of Area, C, D min% | Brinell Hardness, HBW | Pipe | Bar | Forging | Fitting | |

| min ksi | min MPa | min ksi | min MPa | |||||||||||

| Incoloy 800 | UNS N08800 | Annealed | 75 | 515 | 30 | 205 | 30 | 192 | B407 | B408 | B564 | B366 | ||

| Incoloy 800H | UNS N08810 | Annealed | 65 | 440 | 25 | 170 | 30 | 192 | B407 | B408 | B564 | B366 | ||

| Incoloy 825 | UNS N08825 | Annealed | 85 | 586 | 35 | 240 | 30 | B423 | B425 | B564 | B366 | |||

| Alloy 20 | UNS N08020 | Solution Annealed | 80 | 550 | 35 | 240 | 30 | 50 | B729 | B473 | B462 | B366 | ||

Monel 400

This nickel alloy exhibits characteristics like good corrosion resistance, good weldability and high strength. A low corrosion rate in rapidly flowing brackish or seawater combined with excellent resistance to stress-corrosion cracking in most freshwaters, and its resistance to a variety of corrosive conditions led to its wide use in marine applications and other non-oxidizing chloride solutions.

| Chemical Composition | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Grade Symbal | UNS Designation | Carbon | Manganese | Phosphorus | Sulfur | Silicon | Chromium | Nickel | Molybdenum | Others | |

| Monel 400 | UNS N04400 | 0.3 | 2 | … | 0.024 | 0.5 | … | 63.0 min | … | Cu 28.0-34.0; Fe 2.5 max; | |

| Mechanical Properities and ASTM Specifications | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Grade Symbal | UNS Designation | Condition | Tensile Strength | Tensile Strength | Yield Stegnth | Yield Strength | Elongation in 2in or 4D min% | Reduction of Area, C, D min% | Pipe | Bar | Forging | Fitting | |

| min ksi | min MPa | min ksi | min MPa | ||||||||||

| Monel 400 | UNS N04400 | Annealed | 70 | 483 | 25 | 172 | 35 | B165 | B164 | B564 | B366 | ||

Stellite 6B

This Cobalt Alloy is used in applications where wear, corrosion and high temperature resistance are needed. It is most commonly found in directional drilling tools, aerospace applications, valve parts, shaft sleeves and tools.

| Chemical Composition | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Grade Symbal | UNS Designation | Carbon | Manganese | Phosphorus | Sulfur | Silicon | Chromium | Nickel | Molybdenum | Others | |

| Stellite 6B | UNS R30016 | 0.9-1.4 | 2 | 0.04 | 0.03 | 2 | 28-32 | 3 | 1.5 | Tungsten 3.5-5.5; Fe 3.0 max; Cobalt balance | |

| Mechanical Properities and ASTM Specifications | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Grade Symbal | UNS Designation | Condition | Tensile Strength | Tensile Strength | Yield Stegnth | Yield Strength | Elongation in 2in or 4D min% | Reduction of Area, C, D min% | Bar | Plate | |

| min ksi | min MPa | min ksi | min MPa | ||||||||

| Stellite 6B | UNS R30016 | Solution | 154 | 1063 | 93 | 638 | 5 | 7 | AMS 5894 | AMS 5894 | |

CDA172

Beryllium Copper is notable for its highest strength and hardness compared to commercial copper alloys.

| Chemical Composition | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Grade Symbal | UNS Designation | Be | Co | Cu | Si | Fe | Al | Others | |

| CDA172 | UNS C17200 | 1.8-2.0 | > 0.2 | Remaining | 0.15 | 0.15 | 0.2 | ||

| Mechanical Properities and ASTM Specifications | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Grade Symbal | UNS Designation | Condition | Tensile Strength | Tensile Strength | Yield Stegnth | Yield Strength | Elongation in 2in or 4D min% | Reduction of Area, C, D min% | Hardness | |

| min ksi | min MPa | min ksi | min MPa | |||||||

| CDA172 | UNS C17200 | Solution + Precipitation | 165 | 1137 | 140 | 965 | 3 | 36-45 HRC | ||

Inconel, Incoloy and Monel are trademarks of Special Metals Corporation, Stellite is a trademark of Kennametal Inc., and Hastelloy is a trademark of Haynes International Inc. We offer equivalent products.

Email us

ming@stmtus.com

Call Us

1 (840) 240 9993

Address

17890 Castleton Ste.398 Rowland Height, CA91748 US